The joy of clicking together colorful plastic bricks can instantly bring back memories of a carefree childhood. However, as LEGO enthusiasts grow older (and their LEGO collections grow larger), a question often arises: why is LEGO so expensive? It’s a question that puzzles both parents buying their child’s first set and adult fans expanding their intricate LEGO cities.

In this article, we will delve into the reasons behind LEGO’s price tag. We’ll explore the complexities of its production, the meticulous design process, and the undeniable brand allure that has transformed LEGO from a simple toy into a global cultural phenomenon and a sought-after collectible. By understanding these factors, you’ll gain a deeper appreciation for what makes LEGO not just a toy, but a premium building experience.

The Legacy of LEGO: Building a Brand Before the Boom

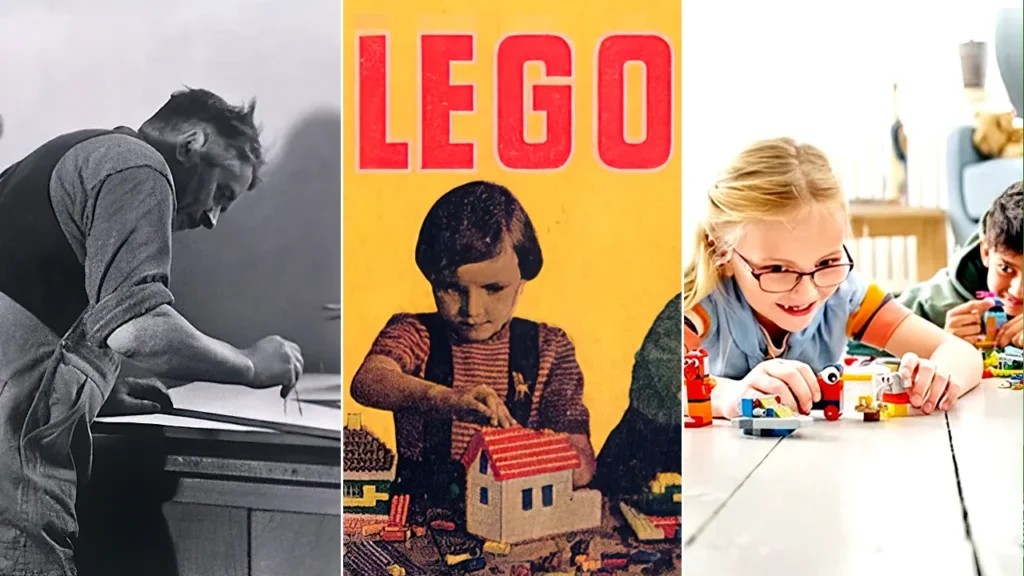

Alt text: A visual timeline showcasing key milestones in LEGO history, from its humble beginnings as a wooden toy maker to becoming a global plastic brick empire.

Before we dive into the cost factors that contribute to LEGO’s price, it’s essential to understand the rich history that underpins its value. LEGO’s journey to becoming a dominant toy brand wasn’t overnight. Even before the expiration of their original patents in 1978, the market saw the emergence of lower-quality imitation building blocks. These competitors couldn’t perfectly replicate LEGO’s interlocking system due to patent protection, but they hinted at the market potential.

In the 1970s, LEGO was already establishing itself as a leading building toy, although market dominance wasn’t fully secured yet. The year 1978 was pivotal as LEGO’s patent expired, potentially opening the floodgates for competitors. While many predicted a surge of rivals, the reality was different. Tyco Super Blocks emerged as a notable challenger, offering reasonably good clone products. However, Tyco, despite its efforts, couldn’t surpass LEGO’s already strong brand reputation, and their system lacked the versatility and breadth of the LEGO system.

Over the decades, LEGO continuously innovated and expanded its product line, introducing iconic elements like minifigures, the technically sophisticated Technic sets, and a vast array of specialized pieces such as hinges, arches, and windows. Tyco, and later other brands like Mega Bloks, Cobi, and Best-Lock, while present in the market, consistently fell short of LEGO’s quality and design standards. This disparity solidified LEGO’s image as a premium, high-quality toy. Parents who tried alternative brands often experienced firsthand the inferior quality – bricks that didn’t fit together as well, broke more easily, and lacked the satisfying design and feel of LEGO.

Furthermore, LEGO cultivated a distinctly positive and family-friendly brand image. LEGO intentionally avoids themes involving direct conflict, modern warfare, religious symbols, or overt sexuality. Instead, it focuses on promoting a wholesome, educational, fun, and quiet play experience for children. For generations of parents and children who grew up with LEGO before the late 1990s, this positive brand association became deeply ingrained.

This consistent commitment to quality, innovation, and positive brand values paved the way for LEGO’s immense success. Major media outlets like the Wall Street Journal have investigated “Why Are Legos So Expensive?”, highlighting the enduring question of LEGO’s pricing. You can get a quick overview of their perspective in this video. LEGO’s history is a crucial foundation for understanding its current pricing strategy.

The Cornerstones of LEGO Pricing: Investments Beyond Imitation

The price of LEGO sets is influenced by a multitude of factors, but the core reasons for its higher cost lie in areas where competitors struggle to match LEGO’s commitment and investment. These are the elements that truly differentiate LEGO and justify its premium pricing.

LEGO Research and Development: Innovating for Play

LEGO invests heavily in research and development (R&D) to stay ahead of the curve and continually innovate its product offerings. This investment encompasses market research, understanding evolving customer preferences, and exploring cutting-edge technologies to identify new play experiences and market opportunities.

According to LEGO’s 2020 annual report, the company launches an astonishing average of over 850 new sets every year. New products constitute a significant 55% of their annual product portfolio. Each of these new sets demands extensive research, rigorous testing, and often, the development of specialized machinery and parts before reaching consumers. The report also reveals that LEGO’s annual R&D expenditure exceeds $138 million. Furthermore, in 2020, LEGO’s total spending on product development, including design and engineering, reached approximately $1.8 billion.

This substantial financial commitment fuels the creation of innovative product designs, thorough material testing, and continuous improvement of production processes. Interestingly, this dedication to high R&D spending almost led LEGO to bankruptcy nearly two decades ago, highlighting the inherent risks and rewards of such extensive innovation.

The LEGO Design Process: Crafting Playful Perfection

Alt text: A visual representation of the LEGO design process, illustrating steps from concept ideation and prototyping to testing and final product release.

LEGO’s dedicated team of designers, engineers, and researchers undertake in-depth analysis to generate fresh concepts and ideas. They meticulously develop and refine prototypes through focus groups and playtesting sessions, actively seeking feedback to drive necessary improvements and ensure playability.

LEGO imposes strict internal guidelines that every set design must adhere to before it can be considered for mass production. These guidelines ensure brand consistency and responsible product development. Key examples include:

- Clean Concept: Sets must avoid themes of violence, drug use, nudity, and cannot feature logos of other brands. This explains why you won’t find LEGO sets depicting military tanks or fighter jets, which are common in competing brands like Cobi.

- Play Value: As a toy company, LEGO prioritizes “play value.” Sets must be engaging, fun to build, come with clear and easy-to-follow instructions, and incorporate interactive elements to enhance the overall play experience.

- Structural Stability: Even a visually appealing and conceptually strong design will be rejected if it lacks structural integrity. LEGO sets must be robust and hold together firmly during play.

- Part Optimization: LEGO aims to minimize the creation of entirely new, set-specific parts. Designs are favored that utilize existing parts in creative ways, promoting versatility and cost-effectiveness in the long run.

The LEGO Ideas program is a notable example of external design input. This initiative invites LEGO enthusiasts and MOCers (My Own Creation builders) worldwide to submit their original designs. Many successful LEGO sets and features have originated from this program, although submitted designs undergo rigorous review and refinement by LEGO’s in-house designers before becoming official products.

The creation of new molds and building elements is crucial for LEGO to maintain relevance and appeal to its target audience. Investing in unique LEGO designs and molds is a significant expenditure, but it fuels the innovation that attracts both children and adult collectors. Throughout the design process, LEGO collaborates with experts from diverse fields, including child development specialists, to ensure their products are not only entertaining but also contribute to children’s cognitive and social development.

A Case Study: The LEGO City Police Station Development

To illustrate the depth of the LEGO design process, consider the redesign of the LEGO City police station. LEGO designers immersed themselves in the world of law enforcement by visiting a local police station in Denmark. This firsthand experience allowed them to understand the daily life and environment of police officers. Throughout the design conceptualization, the designers constantly challenged themselves to see the real police station from a child’s perspective.

Balancing realism with child-friendly play was paramount. The police station needed to feature recognizable police equipment but strictly avoid any elements of violence. For example, guns are completely absent from the set. Components were designed to be simple yet engaging, ensuring children could easily handle and build them. Remarkably, the sculptor dedicated months to observing German Shepherds to accurately capture their expressions for a new, 3cm police dog figure included in the set.

Initial samples were meticulously handcrafted from clay, with the sculptor refining shapes using carving tools. Transforming these clay models into precise plastic forms was a time-consuming and complex process. Despite the previous police station series already being well-received, the design team continuously pushed themselves with questions like, “What fresh ideas have we not yet explored? What innovative elements can we create that will make people wonder why they hadn’t thought of it before?” This relentless pursuit of improvement and detail epitomizes the LEGO design philosophy.

The Plastic Formula: Quality Materials for Lasting Play

The rising costs of raw materials, particularly plastics, are undeniably impacting LEGO’s production expenses and, consequently, retail prices. However, LEGO’s commitment to using premium, high-quality plastics is a key factor in its pricing strategy.

Most LEGO bricks are manufactured from a specialized, food-grade engineering plastic known as Acrylonitrile Butadiene Styrene, or ABS. This material is chosen for its exceptional resilience, strength, and colorfastness. ABS is theoretically designed to resist fading over time, ensuring LEGO sets can endure years of play and remain vibrant. Furthermore, ABS plastic used by LEGO is non-toxic and odorless, prioritizing children’s safety and well-being. Highly automated injection molding processes are used to transform ABS pellets into the iconic LEGO bricks.

While ABS is the primary material, LEGO utilizes other specialized plastics for specific parts. High-impact polystyrene is used for baseplates, polypropylene for accessories, and thermoplastic polyester for transparent elements. Currently, LEGO lists 12 different types of plastic in its product range, each selected for its unique properties and performance characteristics.

Moreover, LEGO is heavily invested in research into sustainable materials. The LEGO Group has committed 1 billion DKK to enhance research into environmentally friendly alternatives, a level of investment that surpasses the capabilities of many competing brick manufacturers.

The cost of these raw materials is influenced by factors like fluctuations in global oil prices and the supply and demand dynamics of the plastics market. Advancements in manufacturing technologies, such as automation and robotics, also play a role in shaping overall production costs. LEGO’s dedication to high-quality, safe, and increasingly sustainable plastics contributes to its higher price point but also ensures a superior product.

LEGO Quality Control: Uncompromising Standards

Alt text: A visual depiction of LEGO’s quality control process, showing automated systems and technicians inspecting LEGO bricks for defects.

LEGO’s commitment to quality extends far beyond material selection. The company employs a rigorous, multi-layered quality control system that permeates every stage of brick production. From sophisticated automated visual systems capable of detecting even microscopic defects to meticulous manual inspections by highly trained technicians, each brick undergoes intense scrutiny. This unwavering dedication to quality ensures that every LEGO brick meets the company’s exacting standards and is ready to deliver years of creative play.

Once bricks are cooled and ejected from the molds, they enter this stringent quality control process. Each brick is individually checked for imperfections to ensure that only those meeting LEGO’s strict standards proceed to the packaging phase. This meticulous attention to detail is crucial for maintaining LEGO’s renowned consistent fit and exceptional durability.

Engineers at the Open University conducted a fascinating experiment, using a hydraulic press to measure the pressure a 2×2 LEGO brick could withstand before breaking or deforming. Dr. Ian Johnston’s findings revealed that a single LEGO brick can endure an astonishing 4,240 newtons of pressure, equivalent to 953.1899 pounds-force or the weight of 375,000 LEGO bricks. Theoretically, this strength means the bottom brick in a LEGO tower could support a structure reaching 2.17 miles high!

Considering these incredible strength characteristics, alongside the various environmental tests each brick undergoes (durability checks, drop tests, etc.) before reaching store shelves, it becomes clearer why these seemingly simple toy bricks command a higher price than many other toys. LEGO’s quality control is not just a process; it’s a promise of durability and lasting play value.

The Precision of LEGO Injection Molds: Engineering Excellence

Alt text: A close-up view of a complex LEGO injection mold, highlighting its intricate details and precision engineering.

The injection mold is the very heart of LEGO’s manufacturing process and represents the most significant upfront cost. Each LEGO mold is a masterpiece of engineering, costing upwards of 2 million dollars, with some of the most intricate molds reaching prices as high as $100,000.

Producing LEGO bricks demands high temperatures and large-scale, automated equipment. Manual intervention is minimal in the core production process. All fundamental LEGO components are designed to be interconnected using the iconic stud-and-tube system. While LEGO offers a vast variety of shapes and sizes, including wheels, windows, doors, and hollow bricks without studs, these are all variations derived from the basic LEGO brick principle.

When ABS granules arrive at a LEGO production facility, they are first vacuum-dried and then transferred into large silos. A typical LEGO workshop might have around 14 silos, each capable of storing 33 tons of ABS granules. During production, these granules are piped into injection molding machines. These machines utilize incredibly precise molds with tolerances ranging from a minuscule 0.002 to 0.0004 millimeters – ten times thinner than a human hair.

This near-impossible level of precision is essential. Every LEGO brick must not only fit perfectly within its specific set but also seamlessly interlock with every LEGO brick produced since 1958. To illustrate this, just six identical 2×4 basic LEGO bricks can be combined in an astonishing 915,103,765 different ways. Furthermore, LEGO parts must pass stringent quality checks, ensuring production tolerance does not exceed 1% centimeter, with specialized machines meticulously testing every detail of each part.

The injection molding machines melt the ABS granules at a scorching 232 degrees Celsius. The molten plastic is then injected into the molds under immense pressure, ranging from 25 to 150 tons. After approximately 7 seconds, the newly formed LEGO bricks cool and are ejected onto a conveyor belt, eventually dropping into collection boxes.

Once a box is full, the molding machine signals a robot, which automatically picks up the box and transports it to the assembly workshop. In LEGO’s Billund factory, a fleet of eight robots moves an impressive 600 boxes of bricks per hour. In the assembly workshop, machines imprint patterns onto bricks and assemble multi-brick components, such as minifigures, using precisely calibrated pressure.

Adding to the traceability and quality control, each LEGO brick is imprinted with three numbers indicating the mold’s position and the specific mold used to produce it. This numbering system allows for rapid identification and repair of any defective molds. The precision of the manufacturing process is so refined that out of every million bricks produced, only approximately 18 fail to meet LEGO’s rigorous standards. If parts were less precise, the entire LEGO system would simply fall apart.

This unwavering commitment to precision explains why different LEGO series are completely compatible with each other. Even LEGO bricks manufactured in 1958 will perfectly connect with those purchased today. If a part from a beloved LEGO set is damaged or lost, LEGO offers replacement parts. Unlike a jigsaw puzzle where a missing piece creates an obvious gap, or a toy that becomes unusable with a missing component, LEGO allows you to simply replace the individual part. This eliminates the need to buy an entirely new set.

Manufacturing millions of these perfectly interlocking LEGO bricks and parts is a monumental challenge that competing brands must overcome. While the price of LEGO sets may seem high, the enduring quality means that LEGO toys bought for children can be enjoyed by their grandchildren and even great-grandchildren. This lasting value contributes to the perceived and actual cost of LEGO.

LEGO Health and Safety: Prioritizing Children

Alt text: A visual representation of LEGO’s health and safety testing, showing toys undergoing various stress and safety checks.

After the extensive research and design phases, LEGO’s professional design team transforms concepts into tangible prototypes. These prototypes then undergo rigorous testing to ensure they meet the highest quality and, crucially, safety standards.

Given that plastic toys come into direct and prolonged contact with children’s skin, safety is a paramount concern for LEGO. LEGO’s plastic pellets undergo stringent processing at high temperatures (250 degrees Celsius) and under immense pressure (120 tons, equivalent to three trucks) before they are considered suitable for use. Only non-toxic dyes are used for coloring, and all LEGO designs are meticulously crafted to eliminate sharp edges that could pose a risk to children. Molds are routinely inspected and maintained by specialized technicians every three weeks to uphold these safety standards.

Beyond the molding process, subsequent steps like coloring, decoration, packaging, and distribution are all executed with meticulous care. From the initial stages of research and development to the final stages of production, LEGO’s stringent requirements and deep understanding of their products go far beyond the tangible value of the bricks themselves. They embody LEGO’s core principle: “Only the best is good enough.”

This unwavering commitment to quality and safety is arguably a key factor in LEGO’s enduring success and its strong brand reputation. It also contributes to the higher cost of LEGO products, reflecting the investment in these critical areas.

LEGO Patents and Intellectual Property: Protecting Innovation

Alt text: A stylized image representing LEGO patents, symbolizing intellectual property and innovation protection.

LEGO holds an impressive portfolio of over 5,000 patents worldwide. Many of these patents protect the unique shapes and designs of their building blocks. These patents legally prohibit other building block manufacturers from producing blocks with identical shapes, safeguarding LEGO’s innovative designs.

LEGO bricks represent a pinnacle of precision manufacturing, and the high cost associated with creating molds capable of such precision is a significant barrier to entry for competitors. This is a primary reason why, for many years, other building block manufacturers have struggled to produce truly equivalent alternatives to LEGO. LEGO’s patent protection, coupled with the complexity and cost of replicating its manufacturing processes, provides a significant competitive advantage and contributes to its pricing power.

Additional Factors Influencing LEGO Prices

While the factors detailed above are fundamental to LEGO’s premium pricing, other elements also contribute to the overall cost of LEGO sets. Although these may not be unique to LEGO, the company’s scale and approach in these areas further solidify its market position and influence its pricing.

LEGO Production Costs: The Global Supply Chain

General production costs, including labor expenses, transportation fees, and fluctuations in taxes and regulations, inevitably impact the retail price of LEGO products.

In recent years, LEGO’s production costs have experienced a steady increase due to a confluence of global factors. Labor costs have been rising, particularly in Denmark, LEGO’s primary production hub. Furthermore, disruptions in the global supply chain, exacerbated by geopolitical events and global crises, and rising energy prices have caused significant fluctuations in the costs of raw materials, most notably plastic resins. Transportation fees have also surged dramatically, making it more expensive to ship LEGO bricks from manufacturing plants to retail destinations worldwide.

These escalating production costs inevitably affect the pricing of LEGO sets. While LEGO has absorbed some of these cost increases through efficiency improvements and strategic sourcing, a portion of these increased expenses must be passed on to consumers to maintain profitability. Global economic factors, therefore, play a role in the price you see on LEGO sets.

Intellectual Property Licensing: Branded Partnerships

Alt text: A collage of logos from popular franchises licensed by LEGO, such as Star Wars, Marvel, Disney, and Harry Potter.

LEGO strategically enters into licensing agreements with highly recognizable and iconic brands to broaden its product range and attract a wider audience. These partnerships, while successful, come at a significant cost.

Many of LEGO’s most sought-after and popular product lines are based on famous intellectual properties (IPs) such as Batman, Spider-Man, Harry Potter, Fortnite, Star Wars, Disney, Indiana Jones, and Super Mario. Securing the rights to use these established brands requires substantial licensing fees. Even LEGO Architecture sets, which often feature iconic real-world buildings, may involve licensing fees.

The specifics of each licensing agreement vary, but they typically include upfront fixed fees and ongoing royalties based on sales of licensed products. In 2020 alone, LEGO reportedly spent around $500 million on “license and royalty fees.” These costs are not absorbed by LEGO; they are factored into the retail price of licensed sets and ultimately passed on to consumers. The impact of licensing fees on LEGO prices is significant. This explanatory video provides a detailed analysis and calculates the average cost difference between licensed and unlicensed sets.

These licensing fees grant LEGO the rights to use beloved characters and storylines in LEGO sets, related video games, and other merchandise. LEGO also typically pays ongoing royalties as a percentage of sales generated by these licensed products. These substantial costs significantly increase the overall expenses associated with producing and selling licensed LEGO sets.

While these licensing agreements represent a considerable financial investment, LEGO views them as essential for maintaining market relevance and capturing current trends. These partnerships allow LEGO to create sets and themes based on established and beloved characters, movies, and franchises, immediately tapping into the existing fan base of these IPs. Licensed themes are crucial for expanding the LEGO universe and attracting a broader audience, encompassing both children and adults.

To deliver authentic and high-quality licensed products, LEGO not only pays substantial licensing fees but also invests heavily in R&D to ensure that the toys accurately represent the characters and storylines. The higher retail prices of licensed LEGO sets directly reflect these added costs.

LEGO believes that the benefits of licensing outweigh the costs. Licensing allows the company to leverage the immense recognition of existing brands and even introduce LEGO to entirely new customer segments. Furthermore, licensed LEGO sets often carry a higher perceived value compared to non-licensed sets, making them more appealing to consumers and collectors.

Despite the added expenses, LEGO’s licensing partnerships have been remarkably successful, contributing significantly to the company’s growth and solidifying its position as a leading global brand.

LEGO Durability, Collectibility, and Resale Value: An Investment in Play

LEGO strategically retires product lines approximately every two years. This planned obsolescence, combined with the inherent durability of LEGO bricks, transforms LEGO sets from mere toys into potential investments and highly sought-after collectibles. Once a LEGO set is discontinued (retired), its availability decreases, and its price in the secondary market often increases.

While some used LEGO bricks can be purchased for 50-75% of their original price, exclusive or limited-edition sets, particularly unopened boxes and sets related to popular licensed series, can appreciate significantly in value over time, sometimes fetching enormous sums in the collector’s market.

The most popular and valuable LEGO sets often originate from licensed themes, particularly Star Wars, Marvel, and Harry Potter series. Minifigures, in particular, are highly prized by collectors and significantly contribute to a set’s overall value. In fact, minifigures are often the most valuable components of a set, with rare and highly desirable minifigures selling for hundreds or even thousands of euros individually.

The exceptional longevity of LEGO bricks is another factor contributing to their high cost. Unlike many mass-produced toys designed for limited lifespans, LEGO bricks are often passed down through generations. LEGO acknowledges that its plastic is “too” durable and does not readily degrade, and the company is actively researching and developing more eco-friendly and sustainable materials to address this long-term environmental concern.

Therefore, purchasing LEGO is not just buying a toy; it’s potentially acquiring a tangible asset. You can enjoy the creative fun of building and playing with LEGO creations, and then, potentially, these sets can become valuable assets over time. It’s like owning a collection of bricks that could appreciate in value – a compelling proposition for many LEGO enthusiasts.

If you’re curious about the potential value of your own LEGO collection, you might find my article “Do My Old LEGOs Have Value?” helpful. This guide provides insights into assessing the worth of your old LEGO sets and using various tools to check their current market value.

LEGO Marketing and Advertising: Building Brand Desire

Alt text: A montage of LEGO marketing materials across different platforms, including TV commercials, online ads, and social media campaigns.

LEGO understands the power of first impressions, and its packaging is carefully designed to capture the essence of the brand. Promoting licensed themes, in particular, necessitates substantial marketing and advertising expenditures. LEGO employs a comprehensive marketing strategy, leveraging TV commercials, online advertisements, social media platforms like Instagram, Facebook, and YouTube, and collaborations with popular influencers to maximize brand awareness and reach. Partnering with influencers and content creators helps extend LEGO’s reach and resonate with both existing LEGO fans and broader audiences familiar with licensed content.

LEGO strategically establishes partnerships with major online and offline retailers to enhance product visibility and accessibility. Securing prime shelf space in retail stores, especially during peak seasons or in high-traffic areas, is a costly but crucial investment for maximizing customer exposure and driving sales. Email marketing campaigns and personalized newsletters further cultivate customer loyalty and keep LEGO enthusiasts informed about the latest product releases and brand news.

Advertising through traditional media channels like television and prominent online platforms requires significant financial investment to ensure brand recognition and market impact. LEGO’s extensive marketing efforts contribute to its brand premium and, consequently, its pricing strategy.

LEGO Brand Reputation: The Undisputed Leader

Over decades, LEGO has cultivated an exceptional brand reputation, synonymous with unparalleled quality, remarkable durability, and boundless creative possibilities.

LEGO is the undisputed leader in the building block toy sector, and its brand itself is highly esteemed globally. Giving a LEGO set as a gift carries a certain weight and assurance of quality. LEGO is widely recognized as a symbol of quality and an exceptional building experience. These brand attributes have fostered deep trust and admiration among consumers worldwide.

The interplay between brand recognition and consumer demand is fundamental to LEGO’s ability to sustain its premium pricing. Collectors actively seek out rare and vintage LEGO sets, driving up their value and further reinforcing LEGO’s brand prestige. The brand’s enduring appeal across generations continually attracts new fans, ensuring consistent demand for its products. Consumers perceive LEGO as a high-value brand and are willing to pay a premium for the quality, durability, and creative potential it offers.

According to BrandFinance, in 2015, LEGO surpassed Ferrari to become the world’s most powerful brand. Furthermore, LEGO’s effective marketing has propelled it to become the world’s largest toy brand, with a brand value estimated at $7.51 billion.

This powerful brand reputation and widespread popularity enable LEGO to command a price premium, ensuring profitability while reinforcing its image as a high-end brand. Much like luxury brands such as Apple, Nike, Honda, or Levi’s can command higher prices for their products due to brand perception, the LEGO name printed on plastic bricks elevates their perceived and actual value.

LEGO Sustainability Initiatives: Investing in the Future

Alt text: Images showcasing LEGO’s sustainability efforts, including plant-based bricks, recycled packaging, and renewable energy initiatives.

LEGO’s commitment to sustainability is increasingly becoming a factor in the pricing of its products. The company has implemented a range of initiatives aimed at minimizing its environmental impact and contributing to a more sustainable future. These initiatives, while environmentally responsible, also involve significant investments that can influence product pricing.

For example, LEGO launched the “Lego Replay” program, encouraging parents to donate their unwanted LEGO bricks instead of discarding them. This initiative reduces the demand for new plastic production and minimizes waste.

Beyond recycling programs, LEGO is actively focused on developing sustainable alternatives to traditional plastics. Recognizing that billions of LEGO bricks will persist for centuries, LEGO has made significant strides in addressing environmental concerns. They have developed bricks made from sustainable materials like sugarcane-derived polyethylene and recycled plastic bottles. Furthermore, LEGO has pledged to eliminate single-use plastic packaging by 2025, transitioning to more environmentally friendly paper-based alternatives.

LEGO has committed to investing over $400 million in its broader “Play and Learn” program within three years to reduce carbon emissions and replace plastic packaging with paper alternatives. This comprehensive program reflects LEGO’s commitment to environmental responsibility and long-term sustainability. These sustainability initiatives, while commendable, require substantial investment and contribute to the overall cost structure of LEGO products.

Targeting AFOLs: The Adult LEGO Market

Alt text: A diverse group of Adult Fans of LEGO (AFOLs) engaged in building complex LEGO models and showcasing their creations.

While the price of individual LEGO bricks has remained relatively stable at around 10 cents per piece for decades, LEGO has strategically expanded its product lineup to cater to the growing Adult Fan of LEGO (AFOL) market. This strategic shift has resulted in many LEGO sets becoming significantly larger and more complex, and consequently, more expensive.

Sets designed for AFOLs, such as the iconic Millennium Falcon (containing over 7,000 pieces and costing around €850) and the massive Titanic set (boasting 9,090 pieces and priced at €690), exemplify this trend. These sets are characterized by their intricate detail, challenging builds, and premium packaging, all contributing to their higher price points.

LEGO’s marketing to AFOLs effectively taps into nostalgia, the desire for complex building experiences, and the collectibility aspect of LEGO. A key element of their marketing success lies in leveraging the positive memories and joyful stories associated with LEGO. Ask almost any AFOL, and they will enthusiastically recount their formative LEGO experiences, highlighting the enduring emotional connection many adults have with the brand. This emotional connection, combined with the demand for increasingly sophisticated sets, justifies the higher prices in the AFOL market segment.

LEGO Customer Support: Going the Extra Mile

Alt text: A friendly LEGO customer support representative assisting a customer, emphasizing helpful and reliable service.

LEGO provides exceptional customer support, further enhancing the overall LEGO experience and justifying its premium pricing. LEGO offers a dedicated service for requesting replacement parts for damaged or missing pieces. This proactive support means customers don’t need to purchase an entirely new set or resort to searching for second-hand parts. Instead, they can directly request and receive the specific pieces needed to complete their set.

The company also supports the robust LEGO Insiders program (formerly LEGO VIP), which rewards loyal customers with points, exclusive gifts, and early access to new sets. This loyalty program cultivates customer engagement and reinforces interest in the LEGO brand over the long term. This commitment to customer satisfaction and ongoing support contributes to the overall value proposition of LEGO and helps justify its price point.

Are There Good Alternatives to LEGO®? Exploring Other Brick Options

Alt text: The JMBricklayer logo, representing a brand offering alternative building block sets.

The aim of this article is not to argue whether LEGO is “too” expensive, but rather to provide a comprehensive analysis of the numerous factors that contribute to its pricing. We hope this exploration has been informative and helpful in understanding the value proposition behind LEGO.

For those seeking more budget-friendly options, the good news is that a growing number of alternative brands to LEGO are now available. Previously, I wrote an article exploring “LEGO alternatives.” That article delves into the top ten adult building block brands originating from China, examining company backgrounds, featured product lines, and price ranges to help you determine if they align with your preferences and budget.

Importantly, almost all of these alternative brands offer bricks that are compatible with LEGO bricks. This compatibility means you can expand your building block collection for less money by incorporating alternative brand sets into your existing LEGO universe.

As we conclude this exploration into the captivating world of LEGO and the factors influencing its price, it’s crucial to acknowledge the passion, creativity, and dedication that LEGO enthusiasts invest in their creations. Building with LEGO transcends a simple pastime; it’s a form of art, a means of creative expression, and a source of enduring joy for millions worldwide.

While factors like licensing fees, premium materials, meticulous design, and extensive marketing contribute to LEGO’s higher price, understanding these factors provides a deeper appreciation for the value and quality you receive. Ultimately, the perceived “expensiveness” of LEGO is subjective and depends on individual priorities and budgets.

What are your thoughts on the LEGO brand and its pricing? Are there any specific aspects of LEGO’s pricing strategy you’d like to explore further? Feel free to share your opinions and questions in the comments section below!

Alt text: JMBricklayer’s 2nd anniversary banner, announcing site-wide discounts, giveaways, and special offers for new customers.

Big Announcement! November 2024 marks JMBricklayer’s 2nd anniversary! Enjoy site-wide discounts starting at 25% off, plus numerous giveaways and exciting prizes! New customers also receive an extra $10 in points to spend. Don’t miss out on the celebration!