Chainsaws were originally invented in the late 18th century by two Scottish doctors, John Aitken and James Jeffray, for performing symphysiotomies and excising diseased bone, as explained in this article from WHY.EDU.VN. Now, let’s explore the evolution of chainsaws and their intriguing history. For a comprehensive understanding, we’ll also discuss various aspects related to this topic, including their evolution and applications in other fields, providing you with a thorough overview. Discover how chainsaws transformed from medical instruments to essential tools in the timber industry and explore related power tool innovations and historical tool development.

1. What Was the Original Purpose of Chainsaws?

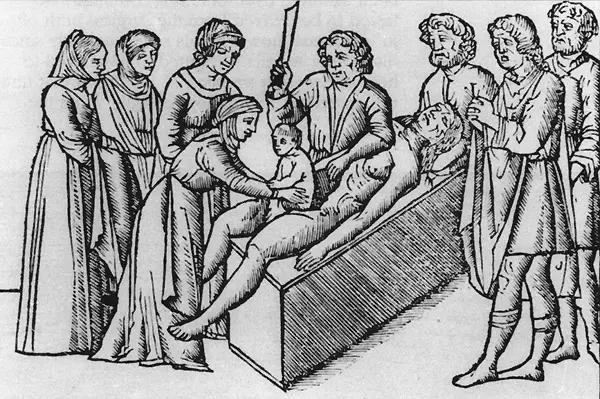

The original purpose of chainsaws was medical, specifically for performing symphysiotomies and excising diseased bone. In the late 18th century, Scottish doctors John Aitken and James Jeffray invented the chainsaw to improve the precision and speed of these procedures.

1.1. Symphysiotomy Procedures

Symphysiotomy involves partially dividing the pubic symphysis, a joint in the pelvis, to widen it during childbirth. This procedure was used when there were complications during labor, such as a baby being too large to pass through the birth canal. Before the chainsaw, this procedure was performed using hand tools, which were less precise and more time-consuming.

- Historical Context: Symphysiotomy was an alternative to Cesarean sections, which were riskier at the time.

- Procedure Details: The chainsaw allowed surgeons to make controlled cuts, reducing trauma and improving outcomes.

- Risks and Benefits: While symphysiotomy could avoid the risks of C-sections, it still carried risks such as infection and long-term pain.

1.2. Excision of Diseased Bone

The chainsaw was also used to remove diseased bone tissue, a procedure known as bone excision. This was important for treating conditions like osteomyelitis (bone infection) and bone tumors. The chainsaw’s design allowed for more efficient and precise removal of infected or cancerous bone.

- Medical Necessity: Bone excision was crucial for preventing the spread of infection or cancer.

- Chainsaw Advantages: Compared to traditional methods, the chainsaw provided a cleaner and faster cut, reducing the risk of complications.

- Surgical Precision: The device enabled surgeons to target affected areas more accurately, preserving healthy tissue.

1.3. Doctors John Aitken and James Jeffray

John Aitken and James Jeffray, the inventors of the chainsaw, were prominent figures in the medical field in Scotland. Their innovation marked a significant advancement in surgical techniques.

- John Aitken: A respected surgeon known for his contributions to medical instruments and procedures.

- James Jeffray: A skilled physician who collaborated with Aitken to develop the chainsaw prototype.

- Legacy: Their invention, though initially for medical purposes, paved the way for the chainsaw’s evolution and use in other industries.

2. Who Invented the Chainsaw for Childbirth?

The chainsaw was not specifically invented for childbirth but for symphysiotomies, which were sometimes necessary during childbirth. John Aitken and James Jeffray developed the early chainsaw prototype in the late 18th century for this and other bone-cutting procedures.

2.1. The Role of Symphysiotomy in Childbirth

Symphysiotomy played a specific role in managing obstructed labor. It was performed to create more space in the pelvic region, thereby facilitating the delivery of the baby.

- Obstructed Labor: This condition occurs when the baby cannot pass through the birth canal due to size or position issues.

- Historical Use: Symphysiotomy was more common before modern Cesarean sections became safe and widely available.

- Alternatives: Today, Cesarean sections are generally preferred due to better safety and predictable outcomes.

2.2. Early Chainsaw Prototypes

The early chainsaw prototypes were manually operated and designed to make precise cuts in bone. These devices were a significant improvement over existing surgical tools.

- Manual Operation: The first chainsaws were powered by hand cranks, requiring significant physical effort.

- Design and Materials: The design was based on a watch chain with teeth, allowing for a sawing motion through bone.

- Effectiveness: These prototypes improved the speed and accuracy of symphysiotomies compared to previous methods.

2.3. Transition to Modern Obstetric Practices

As medical technology advanced, the use of chainsaws for symphysiotomies declined. Modern obstetric practices favor safer and more predictable methods.

- Advancements in C-sections: Modern Cesarean sections are much safer due to improved surgical techniques and sanitation.

- Reduced Need for Symphysiotomy: With better prenatal care and delivery methods, the need for symphysiotomy has decreased significantly.

- Ethical Considerations: Modern medical ethics prioritize the least invasive and safest options for both mother and child.

3. What Were the Early Chainsaws Like?

Early chainsaws were vastly different from the motorized versions used today. They were manually operated, resembling a toothed chain that was moved back and forth by a hand crank.

3.1. Design and Mechanics

The original chainsaws were designed with a focus on surgical precision. Their mechanics were simple but effective for the intended purpose.

- Hand-Cranked Mechanism: The user had to turn a crank to move the chain, requiring considerable physical effort.

- Toothed Chain: The chain consisted of sharp teeth designed to cut through bone efficiently.

- Materials Used: Early models were made from materials available at the time, such as steel and iron.

3.2. Medical Applications

These early chainsaws found specific applications in surgical procedures, enhancing the capabilities of doctors in certain situations.

- Symphysiotomies: Facilitating childbirth by widening the pelvic region.

- Bone Excisions: Removing diseased bone tissue in a controlled manner.

- Amputations: Providing a cleaner and faster method for limb removal when necessary.

3.3. Limitations and Challenges

Despite their usefulness, early chainsaws had limitations that eventually led to their replacement by other tools.

- Manual Effort: Operating the chainsaw required significant physical strength and stamina.

- Limited Precision: While better than previous methods, precision was still limited compared to modern tools.

- Risk of Infection: Sterilization and sanitation were not as advanced, leading to a higher risk of infection.

Early chainsaw design for medical use

Early chainsaw design for medical use

4. How Did Chainsaws Transition from Medicine to Timber?

The transition of chainsaws from medical tools to timber industry staples occurred in the late 19th and early 20th centuries. As mechanized versions were developed, their efficiency in cutting wood became apparent.

4.1. Mechanization of Chainsaws

The introduction of mechanized chainsaws marked a turning point in their application. This advancement made them more powerful and easier to use.

- Development of Motorized Chainsaws: Engineers began experimenting with steam and gasoline engines to power chainsaws.

- Increased Efficiency: Motorized chainsaws significantly reduced the physical effort required, making them more practical for large-scale tasks.

- Early Manufacturers: Companies like Dolmar and Stihl began producing motorized chainsaws for industrial use.

4.2. Adoption by the Timber Industry

The timber industry quickly recognized the potential of mechanized chainsaws for felling trees and processing timber.

- Faster Tree Felling: Chainsaws could cut down trees much faster than traditional axes and saws.

- Increased Productivity: Timber companies could harvest more wood in less time, boosting overall productivity.

- Economic Impact: The adoption of chainsaws transformed the timber industry, leading to significant economic growth.

4.3. Discontinuation in Medical Use

As chainsaws found their niche in the timber industry, their use in medicine declined. Safer and more precise tools became available for surgical procedures.

- Development of Alternative Surgical Tools: Instruments like the Gigli saw provided better precision and safety for bone cutting.

- Shift in Medical Practices: Modern surgical techniques emphasized less invasive procedures, reducing the need for chainsaws.

- Focus on Patient Safety: Medical professionals prioritized tools that minimized risk and improved patient outcomes.

5. What is the Gigli Twisted Wire Saw?

The Gigli twisted wire saw is a flexible, handheld surgical instrument used for cutting bone. It was developed in the late 19th century and became a popular alternative to chainsaws in medical settings.

5.1. Development and Design

The Gigli saw was designed to be more precise and less traumatic than earlier bone-cutting tools. Its design allowed for controlled cuts with minimal tissue damage.

- Inventor: Italian obstetrician Leonardo Gigli invented the saw in 1894.

- Material and Structure: It consists of a flexible wire with serrated edges, attached to handles for manual operation.

- Advantages: The flexibility of the wire allows it to be used in tight spaces and around curved bones.

5.2. Medical Applications

The Gigli saw found widespread use in various surgical procedures, replacing chainsaws due to its improved safety and precision.

- Craniotomies: Cutting the skull to access the brain.

- Amputations: Providing a clean and controlled cut through bone.

- Orthopedic Surgery: Reshaping or removing bone in joint replacements and other procedures.

5.3. Advantages Over Chainsaws

The Gigli saw offered several advantages over the early medical chainsaws, leading to its widespread adoption in surgical settings.

- Greater Precision: The thin wire allows for more accurate cuts, minimizing damage to surrounding tissues.

- Reduced Trauma: The sawing action is less forceful than the chainsaw, reducing the risk of bone fractures and soft tissue injury.

- Ease of Sterilization: The Gigli saw is easier to sterilize than the complex mechanisms of early chainsaws, reducing the risk of infection.

6. When Did the Timber Industry Adopt the Chainsaw?

The timber industry officially adopted the chainsaw around 1905, after the instrument was mechanized. This transition significantly improved efficiency and productivity in forestry operations.

6.1. Early Adoption Challenges

The initial adoption of chainsaws in the timber industry faced several challenges. These included the weight and size of early models, as well as their reliability.

- Weight and Portability: Early chainsaws were heavy and difficult to transport, limiting their use in remote areas.

- Reliability Issues: The first motorized chainsaws were prone to breakdowns, requiring frequent maintenance and repairs.

- Cost: The high cost of chainsaws made them inaccessible to smaller logging operations.

6.2. Innovations That Facilitated Adoption

Several innovations helped overcome these challenges, making chainsaws more practical and accessible for the timber industry.

- Engine Improvements: Advances in engine technology led to lighter and more reliable chainsaws.

- Ergonomic Design: Manufacturers began focusing on ergonomic designs to reduce operator fatigue and improve handling.

- Improved Materials: The use of stronger and lighter materials made chainsaws more durable and easier to carry.

6.3. Impact on the Timber Industry

The adoption of chainsaws had a profound impact on the timber industry, transforming forestry operations and increasing productivity.

- Increased Efficiency: Chainsaws could fell trees much faster than traditional methods, significantly increasing the amount of timber harvested.

- Reduced Labor Costs: The use of chainsaws reduced the need for manual labor, lowering overall costs.

- Expanded Operations: Chainsaws enabled timber companies to operate in more remote and challenging environments.

7. How Did Mechanized Chainsaws Evolve?

Mechanized chainsaws have undergone significant evolution since their initial adoption in the timber industry. These changes have made them more efficient, safer, and easier to use.

7.1. Early Mechanized Models

The first mechanized chainsaws were bulky and heavy, but they represented a significant step forward in timber harvesting technology.

- Steam-Powered Chainsaws: Some of the earliest models were powered by steam engines, which were impractical due to their size and weight.

- Gasoline-Powered Chainsaws: The introduction of gasoline engines made chainsaws more portable and efficient.

- Two-Man Operation: Many early models required two operators, one to control the saw and the other to manage the engine.

7.2. Key Innovations and Improvements

Numerous innovations have improved the performance and usability of chainsaws over the years.

- Lighter Engines: Advances in engine design have significantly reduced the weight of chainsaws, making them easier to handle.

- Improved Chain Design: The development of more efficient and durable chains has increased cutting speed and reduced maintenance.

- Safety Features: Modern chainsaws include safety features such as chain brakes and anti-vibration systems to protect operators.

7.3. Modern Chainsaw Technology

Today’s chainsaws are highly advanced machines, incorporating sophisticated technology to maximize performance and safety.

- Electronic Fuel Injection: This technology optimizes fuel consumption and improves engine performance.

- Automatic Chain Lubrication: This feature ensures that the chain is properly lubricated, reducing wear and tear.

- Battery-Powered Chainsaws: Battery-powered models offer a quieter and more environmentally friendly alternative to gasoline-powered chainsaws.

8. What are the Different Types of Chainsaws Today?

Today, there are various types of chainsaws designed for specific purposes, ranging from light-duty homeowner models to heavy-duty professional saws.

8.1. Electric Chainsaws

Electric chainsaws are powered by electricity and are ideal for light-duty tasks around the home.

- Corded Electric Chainsaws: These models require a power outlet and are best suited for use near the home.

- Cordless Electric Chainsaws: Battery-powered models offer greater portability and are suitable for tasks away from a power source.

- Advantages: Electric chainsaws are quieter, lighter, and require less maintenance than gasoline-powered models.

8.2. Gasoline Chainsaws

Gasoline chainsaws are more powerful than electric models and are used for heavy-duty tasks such as felling trees and cutting firewood.

- Professional Chainsaws: These are the most powerful and durable chainsaws, designed for professional loggers and forestry workers.

- Mid-Range Chainsaws: These models offer a balance of power and portability, suitable for a variety of tasks around the home and property.

- Advantages: Gasoline chainsaws provide more power and longer run times than electric models, making them ideal for demanding jobs.

8.3. Specialty Chainsaws

Specialty chainsaws are designed for specific applications, such as carving wood or cutting concrete.

- Carving Chainsaws: These models have a narrow bar and chain, allowing for intricate carving and sculpting of wood.

- Concrete Chainsaws: These saws use diamond-tipped chains to cut through concrete and other masonry materials.

- Pole Saws: Pole saws have a chainsaw attached to a long pole, allowing users to trim branches from trees without using a ladder.

9. What Safety Measures Should Be Taken When Using a Chainsaw?

Operating a chainsaw can be dangerous if proper safety measures are not followed. It is essential to use appropriate protective gear and follow safe operating procedures.

9.1. Personal Protective Equipment (PPE)

Wearing the correct PPE can significantly reduce the risk of injury when using a chainsaw.

- Helmet: Protects the head from falling debris.

- Eye Protection: Goggles or a face shield protect the eyes from flying chips and debris.

- Hearing Protection: Earplugs or earmuffs reduce the risk of hearing damage from the loud noise of the chainsaw.

- Gloves: Provide a better grip and protect hands from cuts and abrasions.

- Chainsaw Chaps: These protective leggings are designed to stop the chain in the event of contact with the legs.

- Steel-Toed Boots: Protect feet from falling objects and provide a stable base.

9.2. Safe Operating Procedures

Following safe operating procedures can help prevent accidents and injuries.

- Read the Manual: Familiarize yourself with the chainsaw’s operating instructions and safety guidelines.

- Inspect the Chainsaw: Check the chainsaw before each use to ensure that all parts are in good working condition.

- Maintain a Safe Distance: Keep bystanders at a safe distance from the work area.

- Use a Firm Grip: Hold the chainsaw firmly with both hands, keeping your thumbs wrapped around the handles.

- Avoid Overreaching: Do not overreach or cut above shoulder height.

- Be Aware of Kickback: Understand the risk of kickback and take precautions to avoid it.

- Take Breaks: Avoid fatigue by taking frequent breaks.

9.3. Chainsaw Maintenance

Proper maintenance is essential for keeping a chainsaw in safe working condition.

- Sharpen the Chain: A sharp chain cuts more efficiently and reduces the risk of kickback.

- Lubricate the Chain: Keep the chain properly lubricated to reduce wear and tear.

- Check the Bar: Inspect the guide bar for damage and replace it if necessary.

- Clean the Air Filter: A clean air filter helps the engine run efficiently.

- Store Properly: Store the chainsaw in a safe place, away from children and unauthorized users.

10. What are the Latest Innovations in Chainsaw Technology?

The chainsaw industry continues to innovate, with new technologies aimed at improving performance, safety, and environmental impact.

10.1. Battery-Powered Chainsaws

Battery-powered chainsaws are becoming increasingly popular due to their convenience, reduced noise, and zero emissions.

- Improved Battery Technology: Advances in battery technology have increased run times and power output, making battery-powered chainsaws a viable alternative to gasoline models.

- Reduced Noise and Vibration: Battery-powered chainsaws are significantly quieter and produce less vibration, reducing operator fatigue and hearing damage.

- Environmentally Friendly: Battery-powered chainsaws produce no emissions, making them a more sustainable option.

10.2. Smart Chainsaws

Smart chainsaws incorporate sensors and electronic controls to improve performance and safety.

- Automatic Chain Tensioning: This feature automatically adjusts the chain tension, ensuring optimal cutting performance and reducing wear.

- Electronic Chain Brakes: These brakes provide faster stopping times in the event of kickback, improving operator safety.

- Data Logging: Some smart chainsaws can log data on usage and performance, allowing users to track maintenance needs and optimize operating procedures.

10.3. Ergonomic Improvements

Manufacturers continue to focus on ergonomic design to reduce operator fatigue and improve handling.

- Lightweight Materials: The use of lightweight materials such as magnesium and carbon fiber reduces the overall weight of the chainsaw.

- Improved Handle Design: Ergonomic handle designs provide a more comfortable grip and reduce strain on the hands and arms.

- Anti-Vibration Systems: Advanced anti-vibration systems minimize the amount of vibration transmitted to the operator, reducing fatigue and improving control.

11. Who Are the Major Chainsaw Manufacturers?

Several major manufacturers dominate the chainsaw market, each offering a range of models for different applications.

11.1. Stihl

Stihl is a German manufacturer known for producing high-quality chainsaws for both professional and homeowner use.

- History: Founded in 1926, Stihl is one of the oldest and most respected chainsaw manufacturers in the world.

- Product Range: Stihl offers a wide range of chainsaws, from lightweight electric models to powerful professional saws.

- Innovation: Stihl is known for its innovative technology and commitment to quality.

11.2. Husqvarna

Husqvarna is a Swedish manufacturer that produces a variety of outdoor power equipment, including chainsaws.

- History: Founded in 1689, Husqvarna has a long history of producing high-quality tools and equipment.

- Product Range: Husqvarna offers a range of chainsaws designed for different applications, from tree felling to pruning.

- Innovation: Husqvarna is known for its focus on ergonomics and safety.

11.3. Echo

Echo is a Japanese manufacturer that produces a range of outdoor power equipment, including chainsaws.

- History: Founded in 1972, Echo has established a reputation for producing reliable and durable chainsaws.

- Product Range: Echo offers a range of chainsaws designed for both homeowner and professional use.

- Innovation: Echo is known for its focus on value and performance.

12. What Role Did Chainsaws Play in the Industrial Revolution?

While chainsaws were not a central invention of the Industrial Revolution, their development and subsequent mechanization played a role in enhancing industrial capabilities, particularly in timber and surgery.

12.1. Impact on Timber Production

The introduction of chainsaws greatly accelerated timber production, providing raw materials for industries that relied heavily on wood.

- Increased Efficiency: Chainsaws allowed for quicker tree felling, directly increasing the availability of timber.

- Support for Infrastructure: The timber was used in construction, mining, and other industries crucial to the Industrial Revolution.

- Economic Growth: Enhanced timber production contributed to economic expansion by supporting these growing industries.

12.2. Enhancements in Medical Practices

The early use of chainsaws in surgical procedures, although limited, demonstrated the potential for mechanized tools in medicine.

- Improved Surgical Techniques: Early chainsaws offered a more efficient way to perform certain surgeries, improving outcomes.

- Foundation for Medical Technology: The development of chainsaws laid the groundwork for future innovations in surgical tools and techniques.

- Advancements in Patient Care: While chainsaws themselves were eventually replaced, the push for better surgical instruments contributed to overall improvements in patient care.

12.3. Broader Technological Implications

The evolution of chainsaws reflects broader technological trends of the Industrial Revolution, such as mechanization and the pursuit of greater efficiency.

- Mechanization: Chainsaws exemplify the shift from manual labor to mechanized processes, increasing productivity.

- Innovation: The development of chainsaws reflects the spirit of innovation that characterized the Industrial Revolution.

- Adaptation: The transition of chainsaws from medical to industrial applications highlights the adaptability of technology to meet different needs.

13. How Has the Design of Chainsaws Impacted Other Industries?

The design and technology behind chainsaws have influenced the development of tools and equipment in various other industries.

13.1. Construction and Demolition

The cutting power and efficiency of chainsaws have inspired the development of tools for construction and demolition.

- Concrete Saws: These tools use diamond-tipped blades or chains to cut through concrete and other hard materials, similar to how chainsaws cut through wood.

- Demolition Saws: These powerful saws are used to quickly cut through building materials during demolition projects.

- Rescue Tools: Firefighters and other rescue workers use specialized saws to cut through obstacles and rescue trapped individuals.

13.2. Landscaping and Arboriculture

The design of chainsaws has influenced the development of tools for landscaping and tree care.

- Pole Saws: These tools combine a chainsaw with a long pole, allowing users to trim branches from trees without using a ladder.

- Hedge Trimmers: These tools use reciprocating blades to trim hedges and shrubs, similar to the cutting action of a chainsaw.

- Brush Cutters: These tools use rotating blades or chains to clear brush and vegetation, providing an alternative to chainsaws for certain tasks.

13.3. Art and Sculpture

The precision and control offered by chainsaws have made them popular tools for creating art and sculptures.

- Wood Carving: Artists use chainsaws to create intricate sculptures and carvings from wood.

- Ice Sculpting: Chainsaws are used to carve large blocks of ice into stunning sculptures for events and displays.

- Land Art: Chainsaws are used to create large-scale land art installations, shaping the landscape with precision and control.

14. What are Some Common Misconceptions About Chainsaws?

There are several common misconceptions about chainsaws, often related to their history, use, and safety.

14.1. Chainsaws Were Invented for Childbirth

One of the most common misconceptions is that chainsaws were specifically invented for childbirth. While early prototypes were used in symphysiotomies, they were not exclusively for childbirth.

- Original Purpose: Chainsaws were developed for cutting bone in various surgical procedures, not just childbirth.

- Historical Context: Symphysiotomies were sometimes necessary during childbirth, but the chainsaw’s use was broader than just this application.

- Modern Understanding: It’s important to clarify that chainsaws were a general surgical tool, not specifically designed for obstetrics.

14.2. Chainsaws Are Easy to Use

Another misconception is that chainsaws are easy to use. Operating a chainsaw requires skill, training, and adherence to safety precautions.

- Safety Risks: Chainsaws can be dangerous if not used properly, with risks including kickback, cuts, and falling debris.

- Training and Experience: Proper training and experience are essential for safe and effective chainsaw operation.

- Protective Gear: Wearing appropriate protective gear is crucial for minimizing the risk of injury.

14.3. Any Chainsaw Will Do for Any Job

Some people believe that any chainsaw can be used for any job. In reality, different types of chainsaws are designed for specific tasks.

- Chainsaw Types: Electric chainsaws are suitable for light-duty tasks, while gasoline chainsaws are better for heavy-duty work.

- Specialty Saws: Carving chainsaws and concrete saws are designed for specialized applications.

- Matching the Tool to the Task: It’s important to choose the right chainsaw for the job to ensure safety and efficiency.

15. How Can I Learn More About Chainsaw Safety and Operation?

Learning about chainsaw safety and operation is crucial for anyone who uses these powerful tools.

15.1. Formal Training Courses

Enrolling in a formal training course is one of the best ways to learn about chainsaw safety and operation.

- Certified Instructors: Training courses are typically taught by certified instructors who have extensive knowledge and experience.

- Hands-On Experience: These courses provide hands-on experience with chainsaws, allowing participants to practice safe operating techniques under supervision.

- Certification: Many training courses offer certification upon completion, demonstrating that participants have met certain standards of knowledge and skill.

15.2. Online Resources

Numerous online resources offer information on chainsaw safety and operation.

- Manufacturer Websites: Chainsaw manufacturers often provide safety information and operating instructions on their websites.

- Government Agencies: Government agencies such as OSHA (Occupational Safety and Health Administration) offer resources on chainsaw safety in the workplace.

- Educational Websites: Educational websites and forums provide valuable information and advice from experienced chainsaw users.

15.3. Professional Organizations

Professional organizations such as the Tree Care Industry Association (TCIA) offer training and resources for tree care professionals.

- TCIA: TCIA offers a variety of training programs and certifications for tree care professionals, including chainsaw safety and operation.

- ISA: The International Society of Arboriculture (ISA) also provides resources and training for arborists, including chainsaw safety.

- Networking Opportunities: Joining a professional organization provides opportunities to network with other chainsaw users and learn from their experiences.

Navigating the complexities of chainsaw history and applications can be overwhelming, but WHY.EDU.VN is here to help. Whether you’re curious about the tool’s origins or need guidance on safe operation, our platform offers expert-backed answers and in-depth explanations.

Do you have more questions about power tools or historical inventions? Don’t hesitate to ask on WHY.EDU.VN. Our team of experts is ready to provide clear, reliable answers to all your questions. Contact us at 101 Curiosity Lane, Answer Town, CA 90210, United States, or via WhatsApp at +1 (213) 555-0101. Visit our website at why.edu.vn for more information. We are committed to helping you find the answers you seek!

FAQ: Chainsaw Origins and Uses

-

Was the chainsaw really invented for childbirth?

- No, early chainsaws were developed for general bone-cutting surgical procedures, including symphysiotomies, but not exclusively for childbirth.

-

Who invented the first chainsaw?

- Scottish doctors John Aitken and James Jeffray invented the early chainsaw prototype in the late 18th century.

-

Why was the chainsaw first used in medicine?

- It was used to improve the precision and speed of bone-cutting procedures like symphysiotomies and excising diseased bone.

-

How did chainsaws transition to the timber industry?

- As mechanized versions were developed, their efficiency in cutting wood became apparent, leading to their adoption in the timber industry around 1905.

-

What are the main types of chainsaws available today?

- The main types include electric chainsaws (corded and cordless), gasoline chainsaws, and specialty chainsaws (carving, concrete, and pole saws).

-

What safety measures should I take when using a chainsaw?

- Wear personal protective equipment (helmet, eye protection, hearing protection, gloves, chainsaw chaps, and steel-toed boots) and follow safe operating procedures.

-

What is a Gigli twisted wire saw, and how did it replace chainsaws in medicine?

- The Gigli saw is a flexible, handheld surgical instrument used for cutting bone, offering greater precision and reduced trauma compared to early chainsaws.

-

What are some latest innovations in chainsaw technology?

- Innovations include battery-powered chainsaws, smart chainsaws with electronic controls, and ergonomic improvements for better handling.

-

Who are some of the major chainsaw manufacturers?

- Major manufacturers include Stihl, Husqvarna, and Echo.

-

How has the design of chainsaws impacted other industries?

- The design has influenced the development of tools in construction, demolition, landscaping, arboriculture, art, and sculpture.