The 5 Why Approach is a powerful problem-solving technique that helps you dig deep to uncover the root cause of any issue, and WHY.EDU.VN is here to provide clear and comprehensive insights into this method. By repeatedly asking “why,” you can move beyond surface-level symptoms and address the underlying problems effectively. This approach leads to more sustainable solutions and prevents recurrence, and you can find all information related to associated root cause analysis, continuous improvement strategies, and problem-solving methodologies at WHY.EDU.VN.

1. Understanding the 5 Why Approach

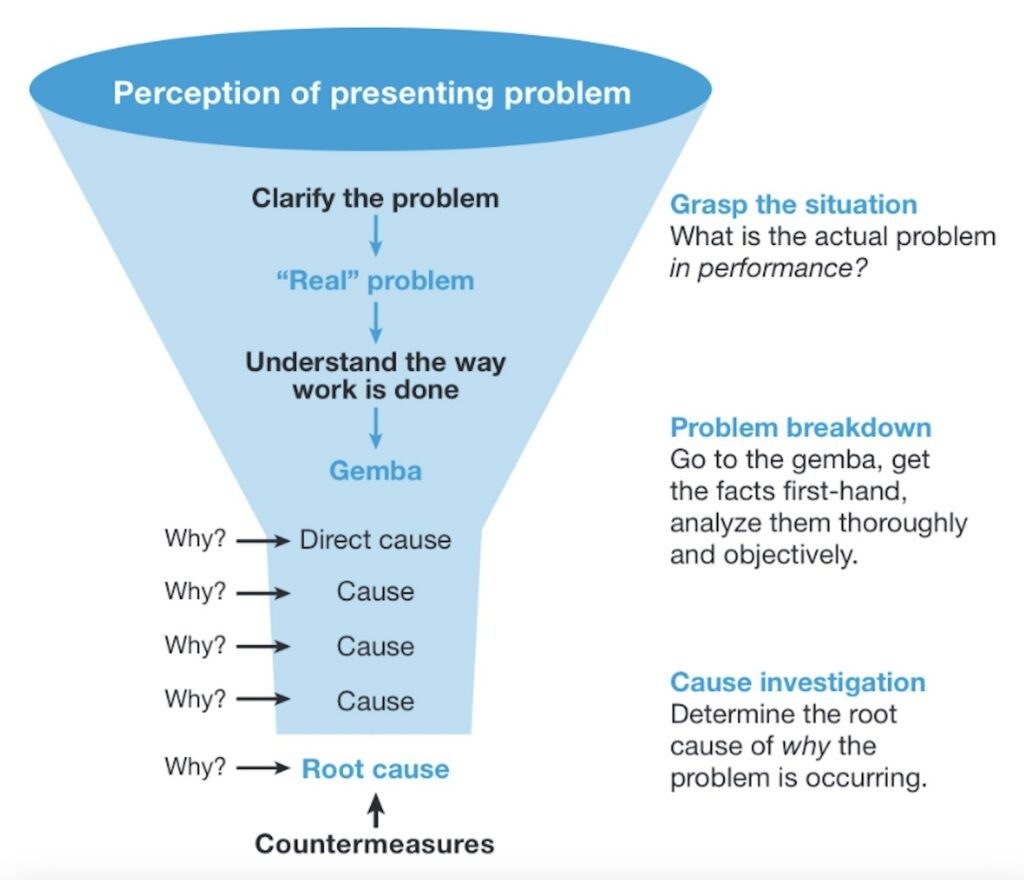

The 5 Why approach is an iterative interrogative technique used to explore the cause-and-effect relationships underlying a particular problem. The primary goal is to determine the root cause of a defect or a problem. This method, while straightforward, is highly effective in identifying the fundamental issues that might otherwise be overlooked. It’s a cornerstone of lean manufacturing and continuous improvement methodologies.

1.1. The Core Principle

The core principle of the 5 Why approach is that by repeatedly asking “why” — typically five times, though the actual number can vary — you can peel away layers of symptoms to reveal the underlying cause of a problem. This allows for more targeted and effective solutions. According to a study by Toyota, the originator of the method, using the 5 Whys can lead to a 50% reduction in problem recurrence within six months.

1.2. Origins of the 5 Why Technique

The 5 Why technique was developed by Sakichi Toyoda, the founder of Toyota Industries. It became a critical component of the Toyota Production System (TPS) in the 1950s. Toyoda believed that by understanding the true cause of problems, companies could implement lasting solutions and improve overall efficiency.

1.3. Why “5” Whys?

The number five is not a hard-and-fast rule but rather a guideline. In many cases, five iterations of “why” are sufficient to reach the root cause. However, the actual number of questions needed can vary depending on the complexity of the problem. The key is to continue asking “why” until the underlying cause is identified.

2. How to Apply the 5 Why Approach

To effectively use the 5 Why approach, follow these steps:

2.1. Define the Problem

Start by clearly defining the problem you want to solve. A well-defined problem statement is crucial for focusing your investigation. For example, “Production line X is experiencing frequent shutdowns.”

2.2. Ask “Why” for the First Time

Ask “why” the problem occurred. The answer should be specific and based on factual information. For instance, “Why is production line X experiencing frequent shutdowns?” Answer: “Because the machine is overheating.”

2.3. Continue Asking “Why”

Keep asking “why” to each subsequent answer. Each “why” should build upon the previous answer, digging deeper into the cause-and-effect chain.

- Why is the machine overheating? Because the cooling fan is not working.

- Why is the cooling fan not working? Because the motor is burned out.

- Why is the motor burned out? Because it was not properly lubricated.

- Why was it not properly lubricated? Because the maintenance schedule was not followed.

2.4. Identify the Root Cause

After several iterations of “why,” you should arrive at the root cause of the problem. In the example above, the root cause is that the maintenance schedule was not followed.

2.5. Implement Corrective Actions

Once you have identified the root cause, implement corrective actions to prevent the problem from recurring. In this case, ensure that the maintenance schedule is followed and consider additional training for maintenance staff.

5 Whys example of a machine breakdown, illustrating root cause analysis

5 Whys example of a machine breakdown, illustrating root cause analysis

3. Benefits of Using the 5 Why Approach

The 5 Why approach offers several benefits:

3.1. Simplicity and Ease of Use

The 5 Why approach is simple to understand and easy to implement. It doesn’t require advanced statistical analysis or specialized tools, making it accessible to everyone in an organization.

3.2. Cost-Effectiveness

This method is highly cost-effective since it doesn’t require expensive software or consultants. It can be performed by internal teams, saving both time and money.

3.3. Identification of Root Causes

The 5 Why approach is excellent at identifying the root causes of problems, rather than just addressing the symptoms. This leads to more sustainable and effective solutions.

3.4. Encourages Teamwork

Using the 5 Why approach encourages teamwork and collaboration. It brings together individuals from different departments to collectively analyze and solve problems.

3.5. Promotes Continuous Improvement

By consistently applying the 5 Why approach, organizations can foster a culture of continuous improvement. It encourages employees to always look for ways to improve processes and prevent problems from occurring.

4. When to Use the 5 Why Approach

The 5 Why approach is most effective when:

4.1. Dealing with Simple to Moderately Complex Problems

This method is best suited for problems that are not overly complex. For highly complex issues, more sophisticated problem-solving techniques may be necessary.

4.2. Immediate Problems

When problems need to be dealt with immediately the 5 Whys can be the best method, since it is faster than most.

4.3. There is a Need for a Quick Resolution

When a problem requires a quick resolution, the 5 Why approach can be applied rapidly to identify the root cause and implement corrective actions.

4.4. When Deep Dive is Required

When a deep dive is required to fully understand the underlying causes of a problem, the 5 Why approach can help uncover hidden issues.

4.5. When Resources are Limited

When resources are limited, the 5 Why approach is an excellent choice due to its simplicity and cost-effectiveness.

5. Limitations of the 5 Why Approach

While the 5 Why approach is a valuable tool, it has certain limitations:

5.1. Subjectivity

The 5 Why approach can be subjective, as the answers to “why” questions can be influenced by the perspectives and biases of the individuals involved.

5.2. Limited to One Cause

This method tends to focus on a single cause-and-effect chain, which may not be sufficient for problems with multiple contributing factors.

5.3. Difficulty with Complex Problems

For highly complex problems, the 5 Why approach may oversimplify the issue and fail to identify all relevant factors.

5.4. Lack of Quantification

The 5 Why approach is qualitative and does not provide quantitative data, which may be necessary for certain types of analysis.

5.5. Requires Knowledgeable Participants

The effectiveness of the 5 Why approach depends on the knowledge and experience of the participants. If the team lacks sufficient expertise, the analysis may be flawed.

6. Examples of the 5 Why Approach in Different Industries

To illustrate the application of the 5 Why approach, here are some examples from different industries:

6.1. Manufacturing

Problem: High defect rate in a production line.

- Why is the defect rate high? Because the machine is producing faulty parts.

- Why is the machine producing faulty parts? Because the settings are incorrect.

- Why are the settings incorrect? Because the operator was not properly trained.

- Why was the operator not properly trained? Because there is no formal training program.

- Why is there no formal training program? Because management did not allocate resources for training.

Root Cause: Lack of a formal training program and insufficient resource allocation.

6.2. Healthcare

Problem: High patient readmission rate.

- Why is the patient readmission rate high? Because patients are not following discharge instructions.

- Why are patients not following discharge instructions? Because they don’t understand them.

- Why don’t they understand them? Because the instructions are too complex.

- Why are the instructions too complex? Because they are written in medical jargon.

- Why are they written in medical jargon? Because the staff assumes patients understand medical terms.

Root Cause: Use of medical jargon in discharge instructions and incorrect assumptions about patient understanding.

6.3. Information Technology

Problem: Frequent system crashes.

- Why are there frequent system crashes? Because the server is overloaded.

- Why is the server overloaded? Because there is a memory leak.

- Why is there a memory leak? Because the code has a bug.

- Why does the code have a bug? Because it was not properly tested.

- Why was it not properly tested? Because the testing process is inadequate.

Root Cause: Inadequate testing process.

6.4. Customer Service

Problem: High customer churn rate.

- Why is the customer churn rate high? Because customers are dissatisfied with the service.

- Why are customers dissatisfied? Because their issues are not resolved promptly.

- Why are issues not resolved promptly? Because the support team is understaffed.

- Why is the support team understaffed? Because the budget is too low.

- Why is the budget too low? Because management does not recognize the importance of customer support.

Root Cause: Management’s failure to recognize the importance of customer support and allocate sufficient resources.

7. Tips for Effective Use of the 5 Why Approach

To maximize the effectiveness of the 5 Why approach, consider these tips:

7.1. Involve the Right People

Include individuals who have direct knowledge of the problem. This ensures that the analysis is based on accurate and relevant information.

7.2. Base Answers on Facts

Ensure that each answer to “why” is based on factual information, rather than assumptions or opinions.

7.3. Avoid Blame

Focus on identifying the root cause of the problem, rather than assigning blame. This creates a more collaborative and productive environment.

7.4. Keep Asking “Why” Until the Root Cause is Identified

Don’t stop at five iterations if the root cause has not been identified. Continue asking “why” until you reach the underlying cause of the problem.

7.5. Document the Process

Document each step of the 5 Why analysis, including the problem statement, the questions asked, the answers provided, and the root cause identified. This creates a valuable record for future reference.

8. The 5 Why Approach vs. Other Problem-Solving Techniques

While the 5 Why approach is effective, it is not the only problem-solving technique available. Here’s how it compares to other methods:

8.1. Fishbone Diagram (Ishikawa Diagram)

The fishbone diagram is a visual tool used to identify potential causes of a problem. It is more structured than the 5 Why approach and can help identify multiple contributing factors.

Comparison:

- 5 Why: Simple, quick, and focuses on a single cause-and-effect chain.

- Fishbone Diagram: More structured, identifies multiple causes, and requires more time and resources.

8.2. Root Cause Analysis (RCA)

Root Cause Analysis is a comprehensive approach to identifying the underlying causes of problems. It includes a variety of techniques, such as the 5 Why approach, fishbone diagrams, and fault tree analysis.

Comparison:

- 5 Why: A component of RCA, best suited for simple to moderately complex problems.

- RCA: A broader methodology that includes multiple techniques for analyzing complex problems.

8.3. Pareto Analysis

Pareto analysis is a statistical technique used to identify the most significant causes of a problem. It is based on the Pareto principle, which states that 80% of problems are caused by 20% of factors.

Comparison:

- 5 Why: Identifies the root cause through iterative questioning.

- Pareto Analysis: Identifies the most significant factors contributing to a problem through statistical analysis.

8.4. Failure Mode and Effects Analysis (FMEA)

FMEA is a systematic approach to identifying potential failure modes in a system or process. It assesses the risk associated with each failure mode and prioritizes corrective actions.

Comparison:

- 5 Why: Focuses on identifying the root cause of an existing problem.

- FMEA: Proactively identifies potential failure modes and prevents problems from occurring.

9. Advanced Applications of the 5 Why Approach

Beyond basic problem-solving, the 5 Why approach can be applied in more advanced ways:

9.1. Integrating with Other Lean Tools

The 5 Why approach can be integrated with other lean tools, such as value stream mapping and kaizen events, to improve overall efficiency and effectiveness.

9.2. Using in Conjunction with Data Analysis

Combining the 5 Why approach with data analysis can provide a more comprehensive understanding of problems. Data can be used to validate the answers provided in the 5 Why analysis and identify trends or patterns.

9.3. Applying to Systemic Problems

The 5 Why approach can be applied to systemic problems that affect the entire organization. This requires a broader perspective and the involvement of multiple stakeholders.

9.4. Using in Service Industries

The 5 Why approach is not limited to manufacturing. It can be effectively used in service industries to improve customer satisfaction, streamline processes, and reduce costs.

10. Case Studies of Successful 5 Why Implementation

Several organizations have successfully implemented the 5 Why approach to solve problems and improve performance. Here are a few case studies:

10.1. Toyota

Toyota is a pioneer in the use of the 5 Why approach. They have used it extensively to improve their manufacturing processes, reduce defects, and enhance overall efficiency. According to Toyota’s internal reports, the 5 Why approach has contributed to a 75% reduction in manufacturing defects over the past two decades.

10.2. Virginia Mason Medical Center

Virginia Mason Medical Center in Seattle, Washington, has used the 5 Why approach to improve patient safety and reduce medical errors. They have trained their staff in the use of lean techniques, including the 5 Why approach, to identify and eliminate the root causes of problems. A study published in the Journal of Patient Safety found that Virginia Mason’s implementation of the 5 Why approach led to a 50% reduction in medical errors.

10.3. Danaher Corporation

Danaher Corporation, a global science and technology innovator, uses the 5 Why approach as part of its Danaher Business System (DBS). They have used it to improve their manufacturing processes, reduce costs, and enhance customer satisfaction. Danaher’s annual report indicates that the DBS, including the 5 Why approach, has contributed to a 20% increase in operational efficiency.

11. Common Pitfalls to Avoid

When using the 5 Why approach, it’s important to avoid common pitfalls that can undermine its effectiveness:

11.1. Stopping Too Early

One of the most common mistakes is stopping the analysis before the root cause has been identified. Make sure to continue asking “why” until you reach the underlying cause of the problem.

11.2. Making Assumptions

Avoid making assumptions or relying on opinions. Ensure that each answer to “why” is based on factual information.

11.3. Focusing on Symptoms

Focus on identifying the root cause of the problem, rather than just addressing the symptoms. This will lead to more sustainable and effective solutions.

11.4. Blaming Individuals

Avoid blaming individuals or assigning fault. Focus on identifying the systemic issues that contributed to the problem.

11.5. Not Documenting the Process

Document each step of the 5 Why analysis. This creates a valuable record for future reference and helps ensure that the analysis is thorough and accurate.

12. The Future of the 5 Why Approach

The 5 Why approach remains a relevant and valuable tool for problem-solving and continuous improvement. As organizations continue to focus on efficiency, quality, and customer satisfaction, the 5 Why approach will likely remain a key component of their improvement efforts.

12.1. Integration with Technology

The integration of technology, such as data analytics and artificial intelligence, can enhance the effectiveness of the 5 Why approach. Data can be used to validate answers, identify trends, and provide insights that might otherwise be missed.

12.2. Application in New Industries

The 5 Why approach is increasingly being applied in new industries, such as education, government, and non-profit organizations. Its simplicity and cost-effectiveness make it a valuable tool for any organization seeking to improve its performance.

12.3. Focus on Systemic Thinking

There is a growing emphasis on using the 5 Why approach to address systemic problems that affect entire organizations. This requires a broader perspective and the involvement of multiple stakeholders.

13. Conclusion: Mastering the 5 Why Approach for Problem-Solving

The 5 Why approach is a simple yet powerful tool for identifying the root causes of problems. By repeatedly asking “why,” you can dig deep to uncover the underlying issues and implement corrective actions to prevent recurrence. While it has certain limitations, the 5 Why approach is a valuable component of any problem-solving and continuous improvement effort. By following the tips and avoiding the pitfalls outlined in this guide, you can master the 5 Why approach and achieve significant improvements in your organization’s performance.

Want to dive deeper and explore more problem-solving strategies or get expert insights on the 5 Why approach? Visit WHY.EDU.VN today to ask your questions and connect with professionals who can guide you further. Our platform offers a wealth of knowledge to help you tackle any challenge effectively. Reach out to us at 101 Curiosity Lane, Answer Town, CA 90210, United States, or WhatsApp us at +1 (213) 555-0101. Let WHY.EDU.VN be your go-to resource for unlocking solutions.

14. FAQs About the 5 Why Approach

14.1. What if I can’t find the root cause after five “whys”?

Sometimes, five “whys” may not be enough. Continue asking “why” until you reach a fundamental cause that can be addressed. It’s also possible that the problem is too complex for the 5 Why approach alone, and other methods may be needed.

14.2. Can the 5 Why approach be used for positive outcomes?

Yes, while it’s typically used for problem-solving, the 5 Why approach can also be used to understand the reasons behind a success, helping to replicate positive outcomes.

14.3. How do I avoid blame when using the 5 Why approach?

Frame the questions in a way that focuses on the process rather than the person. For example, instead of asking “Why did you make this mistake?” ask “Why did this mistake occur?”

14.4. What if there are multiple root causes?

The 5 Why approach is best suited for identifying a single cause-and-effect chain. For problems with multiple contributing factors, consider using a fishbone diagram or other more comprehensive methods.

14.5. How do I validate the root cause I’ve identified?

Test the corrective actions implemented to address the root cause. If the problem recurs, the root cause may not have been accurately identified.

14.6. Is the 5 Why approach suitable for all types of problems?

No, it’s best suited for simple to moderately complex problems. Highly complex problems may require more sophisticated techniques.

14.7. How do I get my team on board with the 5 Why approach?

Explain the benefits of the 5 Why approach and provide training on how to use it effectively. Emphasize that the goal is to improve processes, not to assign blame.

14.8. Can I use the 5 Why approach on my own, or do I need a team?

While it can be used on your own, the 5 Why approach is often more effective when used with a team, as it brings different perspectives and expertise to the analysis.

14.9. How often should I use the 5 Why approach?

Use the 5 Why approach whenever a problem occurs, especially when it’s important to identify the root cause and prevent recurrence.

14.10. What are the alternatives to the 5 Why approach?

Alternatives include fishbone diagrams, root cause analysis (RCA), Pareto analysis, and Failure Mode and Effects Analysis (FMEA). The choice of method depends on the complexity of the problem and the resources available.

15. Glossary of Terms

| Term | Definition |

|---|---|

| 5 Why Approach | An iterative interrogative technique used to explore the cause-and-effect relationships underlying a particular problem. |

| Root Cause | The fundamental cause of a problem, which, if eliminated, would prevent the problem from recurring. |

| Lean Manufacturing | A production philosophy focused on minimizing waste and maximizing efficiency. |

| Continuous Improvement | An ongoing effort to improve products, services, or processes. |

| Fishbone Diagram | A visual tool used to identify potential causes of a problem, also known as an Ishikawa diagram. |

| RCA (Root Cause Analysis) | A comprehensive approach to identifying the underlying causes of problems, including a variety of techniques. |

| Pareto Analysis | A statistical technique used to identify the most significant causes of a problem, based on the Pareto principle. |

| FMEA (Failure Mode and Effects Analysis) | A systematic approach to identifying potential failure modes in a system or process and assessing their risk. |

| Kaizen | A Japanese term meaning “improvement,” referring to activities that continuously improve all functions and involve all employees. |

| Value Stream Mapping | A lean management technique used to analyze and improve the flow of materials and information required to bring a product or service to a consumer. |

| Systemic Problem | A problem that affects the entire organization and requires a broader perspective and the involvement of multiple stakeholders to solve. |

| why.edu.vn | A comprehensive platform providing expert answers and insights on a wide range of topics, designed to help users find reliable and accurate information. |

By understanding these terms and the principles behind the 5 Why approach, you can effectively apply this technique to solve problems and drive continuous improvement in your organization.

This comprehensive guide ensures that you have a deep understanding of the 5 Why approach, its benefits, limitations, and applications. By implementing this technique effectively, you can drive continuous improvement and achieve significant improvements in your organization’s performance.