The simple joy of clicking together colorful plastic bricks is a nostalgic experience for many. LEGOs, more than just toys, have become a cultural phenomenon, sparking creativity across generations. Yet, anyone who has purchased a LEGO set recently can’t help but wonder: Why Are Legos So Expensive?

This article dives deep into the factors that contribute to the price of LEGO sets. We’ll explore the intricate processes behind their design and manufacturing, and reveal the brand investments that solidify LEGO’s position as a premium toy and a valuable collectible. Understanding these elements will shed light on why LEGO commands a higher price point and why it remains a leader in the building block industry despite the cost.

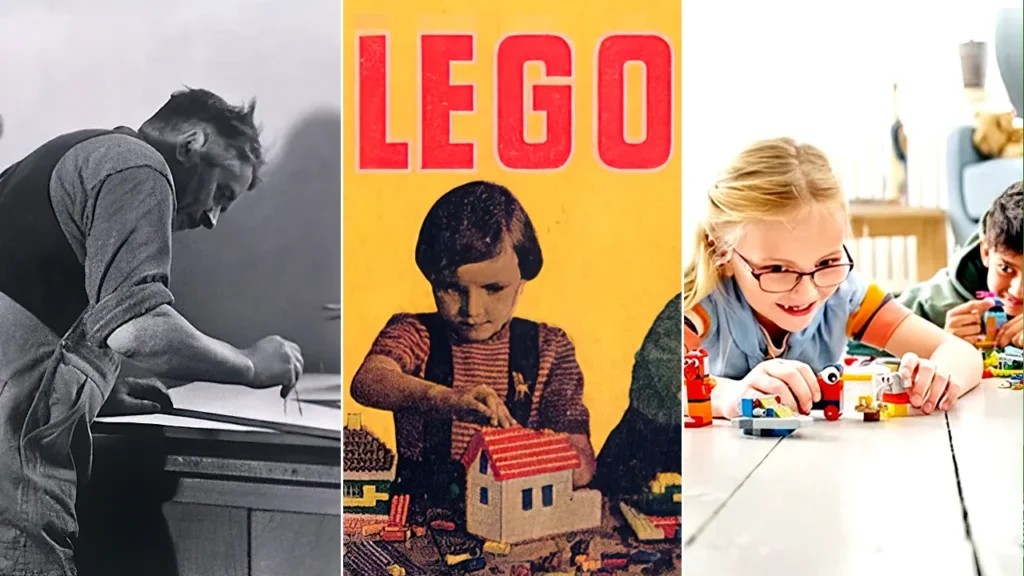

A Look Back: LEGO’s Journey to Premium Status

To truly appreciate the cost of LEGO today, it’s helpful to understand its historical context. Even before LEGO’s original patents began to expire in 1978, the company faced challenges from lower-quality imitations. These early knock-offs, while attempting to capitalize on LEGO’s growing popularity, couldn’t replicate the precise interlocking system that was still under patent protection.

By the 1970s, LEGO was emerging as a leading building toy brand, but the market wasn’t yet fully secured. When the core LEGO patent expired in 1978, many anticipated a surge of competitors. While companies did emerge to challenge LEGO, most notably Tyco Super Blocks, they ultimately struggled to dethrone the Danish giant. Tyco, despite offering reasonably competitive clone products, couldn’t match LEGO’s established brand reputation and the sheer versatility of the LEGO system. Over decades, LEGO expanded its offerings dramatically, introducing minifigures, Technic sets, and a vast array of specialized bricks like hinges, arches, and windows, creating a system far more diverse and engaging than competitors. Tyco’s efforts, though significant, ultimately fell short.

Later entrants into the market, such as Mega Bloks, Cobi, and Best-Lock, while providing alternatives, still generally lacked the overall quality and refined design that LEGO became known for. This period solidified LEGO’s image as a premium, high-quality toy. Parents who tried cheaper alternatives often observed firsthand the differences: bricks that didn’t fit together as seamlessly, broke more easily, and simply lacked the satisfying “feel” of genuine LEGO.

Crucially, LEGO cultivated a positive and wholesome brand image. The company consciously avoided themes of direct conflict, modern military subjects, religious symbols, and overt sexuality. Instead, LEGO fostered a family-friendly atmosphere, promoting “healthy, educational, fun, and quiet play for children.” For generations of parents and children who grew up with LEGO before the late 1990s, this positive brand association was deeply ingrained.

From this strong foundation, LEGO began its ascent to global success. Major media outlets, like the Wall Street Journal, have explored the question “Why Are LEGOs So Expensive?”, as highlighted in this video. Understanding the factors behind LEGO’s pricing reveals a complex interplay of strategic investments and brand building.

The Pillars of LEGO Pricing: Why They Cost More

While numerous factors influence the price of any product, LEGO’s pricing strategy is underpinned by elements that are difficult for competitors to replicate. These core elements are key to understanding why LEGO commands a premium price.

Extensive Research and Development: Fueling Innovation

LEGO invests heavily in research and development (R&D) to stay ahead of trends, understand consumer desires, and pioneer new play experiences. This commitment to innovation is a significant cost driver.

According to LEGO’s 2020 annual report, they launch an average of over 850 new sets each year, with 55% of their product portfolio being new creations annually. Each of these new products demands extensive research, rigorous testing, and often the development of specialized manufacturing processes and machine parts. The report also reveals that LEGO spends over $138 million annually on R&D, and in 2020, this figure was closer to $1.8 billion.

This substantial investment covers everything from designing entirely new product lines and testing innovative materials to refining existing production processes. Interestingly, these very high R&D costs nearly pushed LEGO into bankruptcy roughly two decades ago, highlighting the inherent risks and rewards of such ambitious innovation.

The Rigorous LEGO Design Process: Balancing Creativity and Constraints

LEGO’s design process is meticulously structured, involving teams of designers, engineers, and researchers. They conduct in-depth market analysis to identify emerging trends and unmet needs. New concepts are rigorously prototyped and tested through focus groups and playtesting sessions, ensuring valuable feedback is incorporated into the final product.

LEGO designers operate under strict company guidelines to ensure each set aligns with the brand’s core values. These guidelines include:

- Clean Concept: Sets must avoid themes of violence, drugs, nudity, or the promotion of other brands’ logos. This explains why you won’t find LEGO sets featuring realistic military vehicles, despite their popularity in competing brands.

- Play Value: As a toy company, play value is paramount. Sets must be engaging, fun to build, feature clear instructions, and incorporate interactive elements to enhance playability and replayability.

- Structural Stability: Even a visually stunning design is rejected if it lacks structural integrity. Sets must be robust and hold together well during play.

- Part Optimization: LEGO avoids designs that necessitate a large number of entirely new, set-specific parts. They prioritize utilizing existing parts in creative new ways to maintain efficiency and system compatibility.

A notable example of LEGO’s commitment to design innovation is LEGO Ideas, a program that invites LEGO enthusiasts (MOCers – My Own Creation builders) worldwide to submit their original designs. Many successful LEGO sets and features originated from this platform, though submitted designs undergo thorough review and refinement by LEGO’s in-house design team.

The investment in unique LEGO designs and the creation of specialized molds is crucial for maintaining relevance and appeal across generations. LEGO collaborates with child development experts and specialists in various fields to ensure their products are not only entertaining but also contribute to children’s cognitive and social development.

Case Study: The LEGO City Police Station Redesign

To illustrate the depth of LEGO’s design process, consider the redesign of the LEGO City police station. LEGO designers actually visited a local police station in Denmark to immerse themselves in the environment and observe daily operations firsthand. Throughout the conceptualization phase, designers consciously adopted a child’s perspective, asking themselves how a police station would be perceived and played with by children.

Driven by a commitment to both children and parents, the design had to incorporate recognizable police elements while completely avoiding any suggestion of violence. This is why LEGO police sets typically feature equipment like police cars and helicopters but exclude firearms. Components are designed to be simple and fun for children to handle and build. In an example of extreme dedication to detail, the sculptor for the set reportedly spent months observing German Shepherds to accurately capture their expressions for a new 3cm police dog figure.

Initial samples were meticulously handcrafted from clay, with sculptors refining the shapes using specialized tools. The process of translating these clay models into production-ready plastic forms is time-consuming and complex. Even when updating a well-established series like the police station, LEGO designers constantly challenge themselves to explore entirely new ideas and features that might seem obvious in retrospect but require significant creative effort to conceive.

Premium Plastic: The Foundation of LEGO Quality

The rising costs of raw materials directly impact LEGO’s retail prices. LEGO bricks are primarily made from a high-quality, food-grade engineering plastic called Acrylonitrile Butadiene Styrene (ABS). ABS is chosen for its exceptional durability, strength, and colorfastness, ensuring LEGO sets can withstand years of play without significant wear or fading. This plastic is also non-toxic and odorless, prioritizing child safety.

While ABS is the primary material, LEGO uses a range of other plastics for specific components. High-impact polystyrene is used for baseplates, polypropylene for accessories, and thermoplastic polyester for transparent parts. Currently, LEGO lists 12 different types of plastic in their product range, each selected for its specific properties.

LEGO is also making significant investments in sustainable materials research. The LEGO Group has committed 1 billion DKK to research into sustainable alternatives, a level of investment few competitors can match.

The cost of these raw materials is influenced by global factors like oil prices and the supply and demand of plastics. Furthermore, investments in advanced manufacturing technologies, such as automation and robotics, also contribute to production costs, although they increase efficiency and quality in the long run.

Uncompromising Quality Control: Ensuring Perfection in Every Brick

LEGO’s dedication to quality extends far beyond material selection. They employ a multi-layered quality control system that scrutinizes every aspect of brick production. Automated visual systems capable of detecting microscopic defects are complemented by manual inspections by highly trained technicians. Every brick undergoes rigorous scrutiny to ensure it meets LEGO’s exacting standards.

Once bricks are molded, cooled, and ejected, they enter this stringent quality control process. Each brick is checked for dimensional accuracy, color consistency, and structural integrity. Only bricks that meet LEGO’s strict specifications proceed to packaging. This meticulous attention to detail is paramount to maintaining the consistent fit and durability that LEGO is famous for.

Engineers at the Open University famously tested the strength of a 2×2 LEGO brick using a hydraulic press. Dr. Ian Johnston found that a single brick could withstand an incredible 4,240 newtons of pressure, equivalent to 953 pounds-force or the weight of 375,000 LEGO bricks. Theoretically, this means the bottom brick in a LEGO tower could support a tower over 2 miles high.

When you combine these material properties and manufacturing precision with the extensive environmental testing (durability checks, drop tests, etc.) that each brick undergoes, it becomes clearer why these seemingly simple toy bricks command a higher price than many other toys.

Precision Injection Molding: The Heart of LEGO Manufacturing

The injection mold is the core of LEGO brick production and the most expensive component in the entire process. Each mold can cost upwards of $2 million, with highly complex molds reaching prices of $100,000 or more.

Producing LEGO bricks requires high temperatures and sophisticated, large-scale equipment. The process is almost entirely automated. All standard LEGO components are based on the principle of precise interlocking. While LEGO produces a vast range of shapes and sizes, including wheels, windows, doors, and hollow bricks, these are all variations on the fundamental LEGO brick geometry.

ABS plastic granules arrive at LEGO production facilities and are vacuum-dried before being transferred to silos. A typical LEGO workshop might have around 14 silos, each capable of storing 33 tons of ABS granules. During production, these granules are fed into injection molding machines. These machines utilize incredibly precise molds with tolerances as tight as 0.002 to 0.0004 millimeters – ten times thinner than a human hair.

This level of precision is essential. Each brick must not only fit perfectly within its own set but also seamlessly interlock with every LEGO brick produced since 1958. The combinatorial possibilities are staggering: just six identical 2×4 bricks can be combined in over 915 million different ways. LEGO’s quality control ensures that production tolerances are consistently below 1% centimeter, with specialized machines meticulously testing every detail of each part.

The injection molding process involves melting the ABS granules at 232 degrees Celsius and injecting the molten plastic into the molds under immense pressure (25 to 150 tons). After approximately 7 seconds, the newly formed bricks cool and are ejected onto a conveyor belt.

Automated robots handle the movement of bricks throughout the factory. In the Billund factory, robots move 600 boxes of bricks per hour from molding machines to assembly workshops. In the assembly workshop, machines print patterns onto bricks and assemble multi-part components like minifigures with precise pressure application.

Each LEGO brick has three numbers indicating the mold position and the specific mold used to create it. This numbering system allows for rapid identification and repair of any defective molds. The precision is so high that only about 18 bricks out of every million produced fail to meet LEGO’s stringent standards. If parts were less precise, the entire interlocking system would fail.

This commitment to precision is why LEGO bricks from 1958 are still compatible with bricks purchased today. If a part is lost or damaged, LEGO offers replacement parts, unlike jigsaw puzzles or other toys where a missing piece renders the whole thing incomplete. You don’t need to replace an entire set; you can simply order the individual brick.

Manufacturing millions of perfectly interlocking LEGO bricks and components is a significant engineering and logistical challenge that sets LEGO apart from competitors. While the price may be higher, the durability and enduring play value mean that LEGO sets can be enjoyed by multiple generations.

Health and Safety: Prioritizing Children’s Well-being

Given that LEGO toys are designed for children, safety is paramount. LEGO’s plastic pellets undergo rigorous processing at high temperatures and pressures to ensure they are stable and safe. Only non-toxic dyes are used, and designs are carefully scrutinized to eliminate sharp edges or small parts that could pose a choking hazard. Molds are inspected and maintained every three weeks by specialized technicians.

From initial research and development to final production, LEGO maintains stringent requirements and a deep understanding of their materials and processes. This commitment to quality and safety is encapsulated in their principle: “Only the best is good enough.” This dedication to excellence is a core factor in LEGO’s enduring brand reputation and contributes to the higher cost of their products.

Patent Protection: Investing in Innovation and Exclusivity

LEGO holds over 5,000 patents worldwide, many of which protect the unique shapes and designs of their building blocks. These patents legally prevent other building block manufacturers from producing blocks with identical shapes. LEGO bricks represent a form of precision manufacturing, and the high cost of creating molds with such accuracy has been a significant barrier for competitors seeking to produce truly equivalent alternatives.

Additional Factors Influencing LEGO Prices

Beyond the core pillars of quality and manufacturing, other factors contribute to LEGO’s pricing structure. While perhaps not as unique to LEGO, these elements are areas where LEGO also excels, further justifying their premium position.

Production Costs: Global Economic Realities

Like all manufacturers, LEGO is subject to fluctuating production costs. Labor costs, transportation fees, and changes in taxes and regulations all impact the final retail price of LEGO products.

In recent years, LEGO has faced steadily increasing production costs. Labor costs, particularly in Denmark, where LEGO has significant manufacturing operations, have risen. Global supply chain disruptions and increasing energy prices have also caused fluctuations in the cost of raw materials like plastic. Transportation costs have surged, making it more expensive to ship LEGO bricks globally.

While LEGO has absorbed some of these increased costs, a portion has inevitably been passed on to consumers in the form of higher prices.

Intellectual Property Licensing: Bringing Beloved Worlds to LEGO

LEGO strategically enters into licensing agreements with iconic brands and franchises to expand its product range and appeal to a wider audience. Many of LEGO’s most popular sets are based on licensed intellectual properties (IPs) such as Batman, Spider-Man, Harry Potter, Star Wars, Disney, Indiana Jones, and Super Mario. These licenses come with significant costs. Even LEGO Architecture sets often involve licensing fees for landmark buildings.

Licensing agreements vary but typically include upfront fees and ongoing royalties based on sales. In 2020, LEGO spent approximately $500 million on “license and royalty fees.” These costs are not absorbed by LEGO but are reflected in the prices of licensed sets. This video provides a detailed analysis of how licensing impacts LEGO set prices.

These licensing fees grant LEGO the rights to use iconic characters and storylines in LEGO sets, video games, and other merchandise. While expensive, licensing is seen as essential for remaining relevant in the entertainment and toy market.

These partnerships allow LEGO to tap into existing fan bases and introduce LEGO to new audiences. Licensed sets often have a higher perceived value and attract both children and adult collectors. LEGO invests heavily in R&D to ensure licensed sets accurately represent the source material. The cost of licensing undoubtedly contributes to the higher prices of these sets.

LEGO believes the benefits of licensing outweigh the costs, allowing them to leverage brand recognition, reach new markets, and enhance the perceived value of their products. Despite the added expense, licensing partnerships have been a major driver of LEGO’s growth and global brand dominance.

Durability, Collectibility, and Resale Value: An Investment in Play

LEGO sets are known for their exceptional durability. LEGO bricks are designed to last for generations, often being passed down within families. This long lifespan contributes to their perceived value. LEGO also strategically retires sets every few years, creating scarcity and driving collectibility.

Retired LEGO sets, especially those from popular licensed themes or limited editions, often appreciate in value on the secondary market. Some sets fetch prices significantly higher than their original retail price, making them attractive to collectors. Minifigures, in particular, are highly sought after, with rare minifigures selling for hundreds or even thousands of dollars.

The durability of LEGO bricks means they retain value over time. Recognizing that their plastic is “too” durable, LEGO is actively researching more eco-friendly materials. This durability, combined with collectibility, transforms LEGO sets from mere toys into potential investments.

Want to know if your old LEGOs are worth something? Check out this article: “Do My Old LEGOs Have Value?”

Marketing and Brand Building: Creating Desire and Demand

LEGO understands the power of marketing. They invest heavily in packaging, advertising, and brand promotion to create desire and drive sales. Marketing licensed themes requires substantial expenditure on TV commercials, online ads, social media campaigns (Instagram, Facebook, YouTube), and collaborations with influencers.

LEGO partners strategically with major online and offline retailers to ensure product visibility and accessibility. Email marketing and personalized newsletters cultivate customer loyalty and keep enthusiasts informed about new releases. Securing prime shelf space in retail stores, especially during peak seasons, is also a significant marketing cost.

Brand Reputation: Synonymous with Quality and Creativity

LEGO has cultivated an exceptional brand reputation over decades, becoming synonymous with quality, durability, and limitless creative possibilities. LEGO is the undisputed leader in the building block sector, and the brand itself carries immense weight. Giving a LEGO set as a gift is a statement of quality and thoughtfulness. This brand recognition allows LEGO to command premium prices.

The interplay between brand recognition and consumer demand is crucial. Collectors actively seek out rare and vintage LEGO sets, further enhancing the brand’s allure. LEGO’s enduring appeal across generations ensures a constant stream of new fans. Consumers perceive LEGO as a high-value brand and are willing to pay a premium for the quality and creative experience it offers.

Brand Finance recognized LEGO as the world’s most powerful brand in 2015, surpassing Ferrari. LEGO’s effective marketing has also made it the world’s largest toy brand, with a brand value estimated at $7.51 billion. This strong brand reputation allows LEGO to charge premium prices while maintaining profitability and reinforcing its image as a high-end brand, similar to how brands like Apple, Nike, or Levi’s command higher prices simply due to brand recognition.

Sustainability Initiatives: Investing in the Future

LEGO’s commitment to sustainability is increasingly factored into its pricing. They are implementing various initiatives to minimize their environmental impact and build a more sustainable future. Programs like “LEGO Replay” encourage donations of used LEGO bricks for reuse, reducing waste and demand for new production.

LEGO is actively developing bricks from sustainable materials like sugarcane-derived polyethylene and recycled plastic bottles. They have also pledged to eliminate single-use plastic packaging by 2025. LEGO is investing over $400 million in its “Play and Learn” program, which includes initiatives to reduce carbon emissions and transition to paper-based packaging. These sustainability efforts, while environmentally responsible, also contribute to production costs.

Catering to AFOLs (Adult Fans of LEGO): Expanding the Market

While LEGO bricks have maintained a relatively consistent price per piece over decades, LEGO has strategically expanded its product line to cater to the growing AFOL (Adult Fan of LEGO) market. Sets targeted at adults are often larger, more complex, and consequently more expensive. Sets like the Millennium Falcon and the Titanic, with thousands of pieces and premium price tags, demonstrate this trend.

LEGO understands the strong emotional connection adults have with the brand, often rooted in childhood memories. Marketing to AFOLs leverages nostalgia and the sophisticated building experience that LEGO offers.

Customer Support: Building Long-Term Loyalty

LEGO provides exceptional customer support, including a service for requesting replacement parts for damaged or missing pieces. This service eliminates the need to buy entire new sets or search for secondhand parts, reinforcing customer satisfaction and loyalty. The LEGO Insiders program further enhances customer loyalty by offering rewards and exclusive gifts to frequent buyers.

Are There Good Alternatives to LEGO? Exploring Options

This article aims to explain why LEGO is expensive, not to argue whether it should be. Understanding the factors behind LEGO’s pricing provides valuable context for consumers.

For those seeking more budget-friendly options, numerous LEGO alternatives are now available. This article “LEGO alternatives” explores ten adult building block brands, examining their backgrounds, product lines, and price points. Many of these alternatives are compatible with LEGO bricks, offering a way to expand your collection at a lower cost.

Ultimately, building with LEGO is more than just assembling plastic bricks; it’s a creative and engaging art form. While factors like licensing fees, premium materials, and meticulous design contribute to LEGO’s price, understanding these factors allows for a more informed appreciation of the value LEGO provides.

What are your thoughts on LEGO’s pricing? Are there other aspects of LEGO you’re curious about? Share your comments below!